MEKA GRIZZLY FEEDER

UP to 1000 TPH

Input size up to 1200mm

SUITABLE FOR

Limestone, aggregates, coal, basalt, sand, woodchip, pebble, recycling, iron ore, etc

Grizzly feeders have been designed to excel in the harshest conditions and applications. High abrasion resistance, durable heat-treated drive console and high quality vibrating motors ensure peak efficiency, reliable feeding and effective long-term operation with minimum breakdowns.

Applications

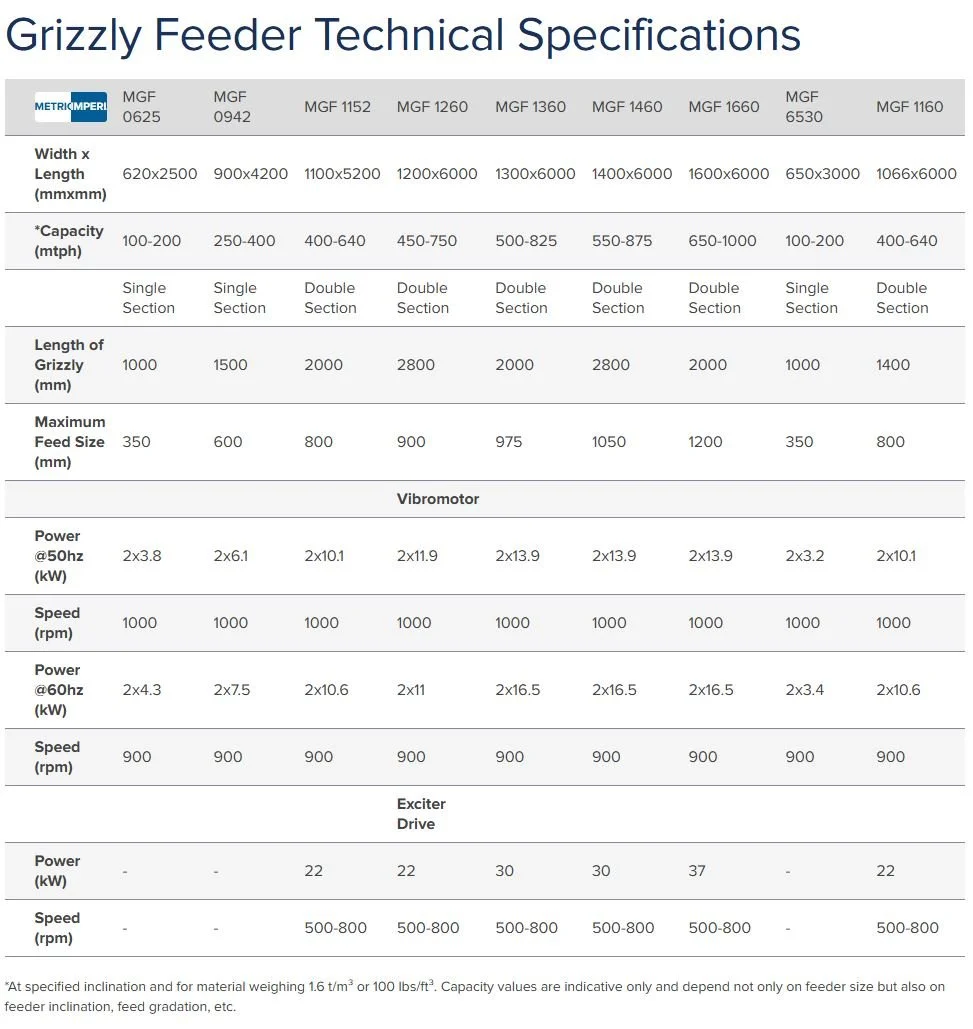

MEKA grizzly feeders come in many sizes to balance demands for capacity, impact resistance, weight and installation dimensions.

They provide high production and long service life in a wide range of rigorous applications.

Why MEKA Grizzly Feeder?

Increases the throughput of your plant

Vibrating action is combined with proper pan design to ensure even distribution of material on the feeder pan and consistent material flow.

Increases the final product quality by removing dirt

Tapered, bolt-in grizzly bars with a deep profile, minimizing the occurrence of plugging and blinding.

Reliably controls feed rate

The dual unbalanced electric motor drive makes a simple stepless feed rate adjustment possible using a frequency converter

Fits to most applications: hard stone, limestone, recycling, gravel…

Wide range of primary grizzly feeders that balance the demands of capacity, impact strength, weight and installation dimensions.

What are Grizzly Feeder?

Grizzly feeders produce a linear motion in their pan and grizzly sections and are used in the primary feeding stage for the simultaneous performance of feeding and separation processes.

The grizzly opening of the feeder is selected according to the feed curve and closed side setting of the crusher to be fed . As a result, material smaller than the crusher setting is prevented from entering the crusher. The dirty material in the feed bypasses the crusher and is fed to a screen to be discarded as waste and the remaining clean material is fed to the post-crusher process.

Although it is possible to install grizzly feeders inclined, horizontal installation is widely preferred for separation efficiency. If an increase in capacity is needed, the installation angle can be increased by several degrees without loss of separation efficiency.