MEKA HAMMER CRUSHER / HAMMERMILL

UP to 150 TPH

Input size up to 100mm

Variable output size from 2mm

SUITABLE FOR

Limestone, fertiliser, basalt, concrete, recycling, etc

The material passes through the feed opening into the striking arc of the rotating hammers. The hammers fling the material against the grinding ledges of the grinding wall, from where it rebounds back against the hammers. The material flow is spread over the following discharge grates, where the product granulometry is separated and discharged through the grates. Any remaining material continues to be processed until it can pass through the grate gap. The grate bar gap spacing determines the final product size. To influence the product size, the circumferential speed of the rotor can be varied.

Applications

Hammer crushers are employed for the fine crushing of medium-hard to soft materials, such as anhydrite, quicklime, lignite, dolomite, gypsum, glass, potash, limestone, china-clay, diatomite, chalk.

Why MEKA Hammer Crusher?

High throughput capacity due to large grinding grate respectively screening area,

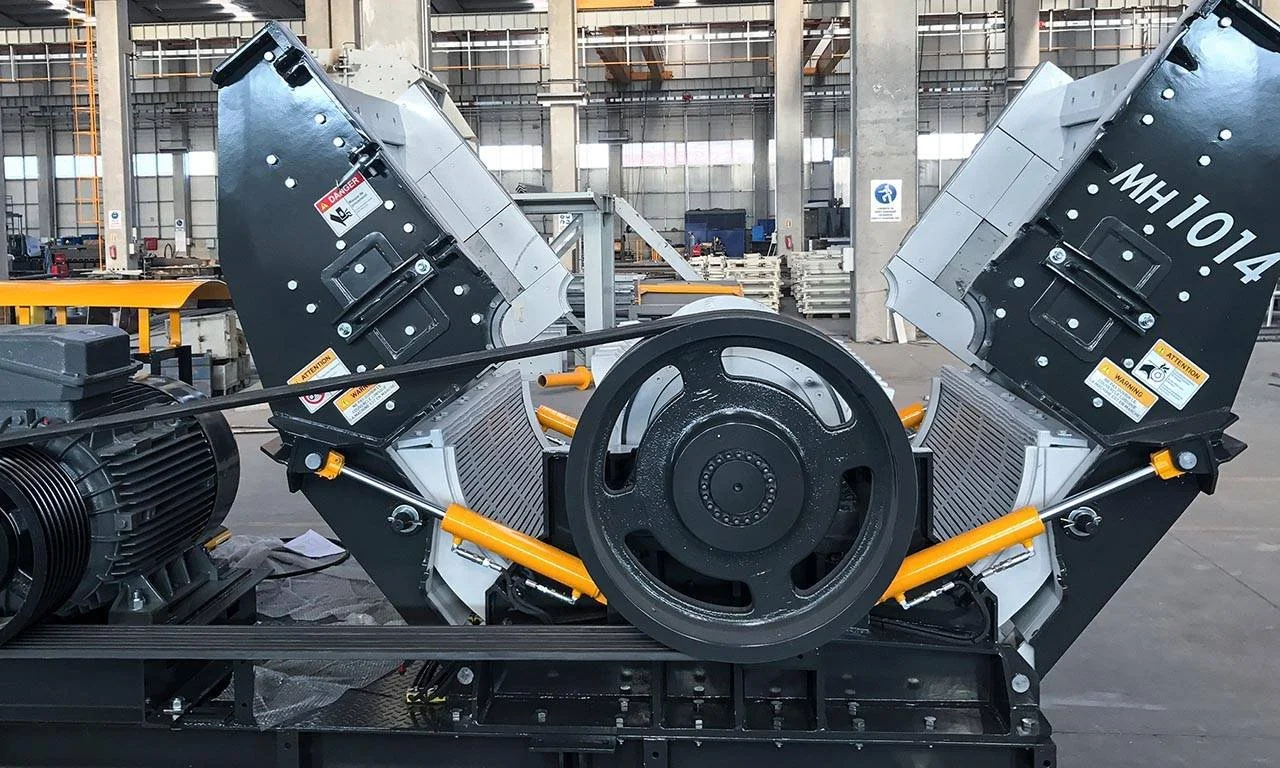

Low space requirements due to extremely low construction height,

Large intake cross-section for bulky feed material,

High and constant capacity,

Easy replacement of wear and spare parts through hydraulic opening device,

Broad range of applications,

High reduction ratio.

Options include feed in chutes, discharge hoppers, stands with walkways, service platforms and stairways, as well as various options for discharge handling (hoppers, chutes, conveyors, etc).