MEKA TERTIARY IMPACT CRUSHER

UP to 320 TPH

Input size up to 150mm

SUITABLE FOR

Limestone, aggregates, coal, sand, basalt, pebble, recycling, iron ore, etc

Tertiary impact crushers are manufactured with different rotor sizes and the required motor power is selected according to the application. The strength of Tertiary impact crushers (MTI) makes them ideal for every kind of application in many different configurations. Tertiary impact crushers (MTI) have demonstrated their effectiveness in many missions from crushing low abrasive materials to industrial applications and recycling.

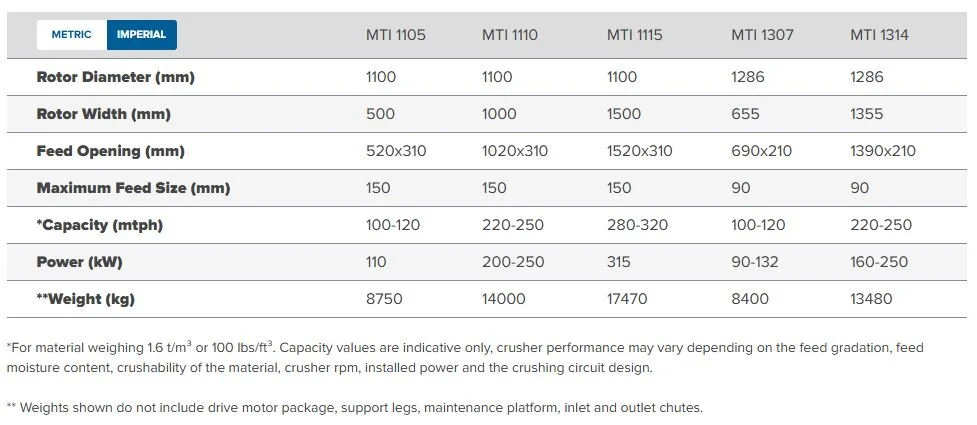

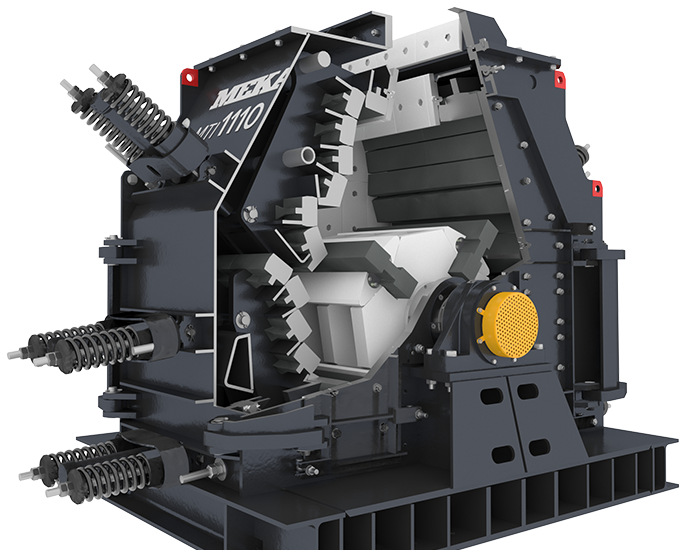

MEKA’s product range includes 2 different designs of tertiary impact crushers. MTI 1105-1110-1115 models are with 4 blowbars mounted on a circular shaped rotor and MTI 1307-1314 models are with 3 blowbars mounted on a oval shaped rotor.

Applications

QUARRIES

Production of aggregates for concrete and asphalt plants,

Production of manufactured sand,

Production of Agricultural Lime / Aglime.

Shaping of flaky aggregates to obtain cubical aggregates.

INDUSTRIAL MINERALS

Production of fine material with minimum capital and operational costs,

Excellent particle shape down to micron sizes,

Why MEKA Tertiary Impact Crusher?

Symmetric Crushing Chamber Allows for better utilization of wear parts

The rotors in our MTI Series crushers are designed to operate in both directions, so when the wear parts are worn out for one side of the crusher, the operators can change the rotor’s operating direction to the other side. This method decreases inventory costs for clients by reducing maintenance requirement time and parts cost.

High-Speed Rotor Produces More Fines

The rotor with high inertia improves reduction ratio and provides stability in the process, reducing energy consumption and increasing long-term performance.

Manufactures sand from limestone and dolomite

High quality and cubical shape products with low filler content

Upto 150mm feed size

Heavy rotor and crushing chamber design in addition to materials selected for their outstanding wear resistance further reducing operating and wear costs.

Options include stands with walkways, service platforms and stairways, as well as various options for discharge handling (hoppers, chutes, conveyors, etc).