MEKA JAW CRUSHER

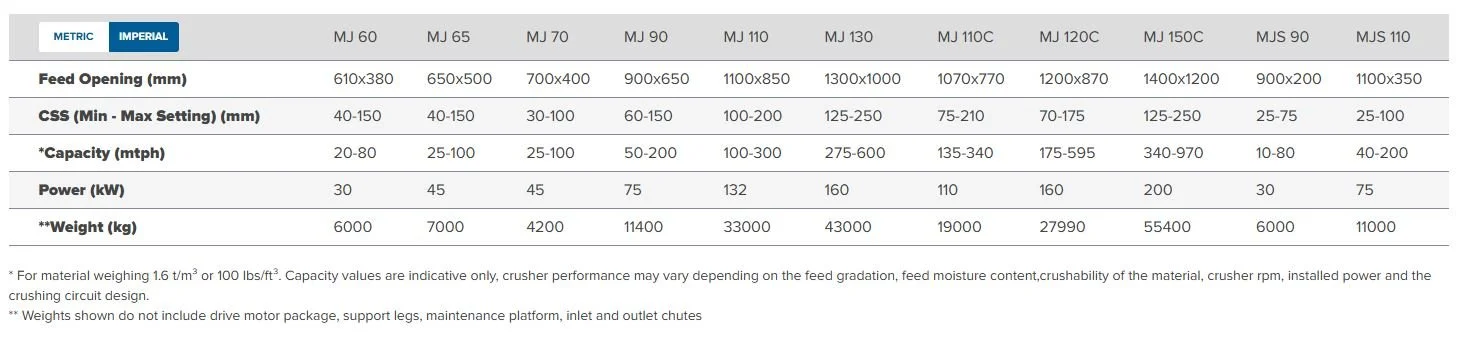

UP to 970 TPH

Input size up to 1400mm

SUITABLE FOR

Limestone, aggregates, coal, sand, basalt, pebble, recycling, iron ore, etc

Meka Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their low-cost operation and easy maintenance. There are also primary and secondary types of these crushers.

Why MEKA Jaw Crusher?

- High capacity,

- High reduction,

- Low jaw plate wear,

- Large feed acceptance capability,

- Optimized nip angle ensures that the material progresses smoothly down through the crushing chamber to enable high reduction, productivity and superb utilization of jaw plates.

Options include stands with walkways, service platforms and stairways, as well as various options for discharge handling (hoppers, chutes, conveyors, etc).