MEKA PRIMARY IMPACT CRUSHER

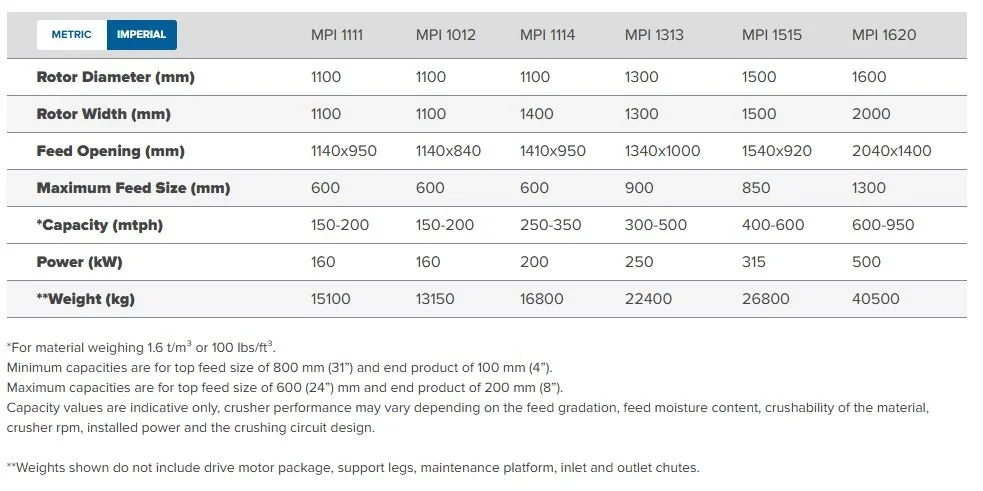

UP to 970 TPH

Input size up to 1400mm

SUITABLE FOR

Limestone, aggregates, coal, sand, basalt, pebble, recycling, iron ore, etc

MEKA Primary Impact Crushers (MPI), offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating conditions where output and productivity demands are increasingly stringent.

Why MEKA Primary Impact Crusher?

Very High Reduction Ratio

Primary Impact Crushers achieve a higher reduction with fewer crushing stages, lowering your capital costs and saving energy. The design of crushing chamber with double breaker plates ensures great reduction ratios and with the addition of a third plate, reduction ratio can even be improved.

Can produce aggregates in a single stage crusher

With the ability to recirculate material to the MPI range of crushers, it is now possible to achieve single stage crushing. This will allow customers to set up a plant for minimal capital outlay and start producing aggregates quickly and simply, thus enabling a relatively quick return on investments.

Can accept big boulders

Large unobstructed feed opening, heavy-duty breaker plates and heavy rotor are designed to accept big feed size for high production.

Very high throughputs

Design of the crusher maximizes loading, and with a bigger crushing chamber, the result is a boost in productivity in every type of application.

Options include stands with walkways, service platforms and stairways, as well as various options for discharge handling (hoppers, chutes, conveyors, etc).